Production index: oil loss is less than or equal to 2%, moisture is less than 0.2%, free fatty acid FFA is less than or equal to 5.5%

Advantage:Energy-efficient, modular assembly, easy to transport and move production

The recycling of factory by-products, self-supply of electricity, high degree of automation, and reduced labor costs.

| 01 |

1.Receiving section of palm fruits bunches Loading ramp:as palm fruit unloading, cleaning, storage platforms, all hydraulic segmented discharge. |

|

| 02 |

2.Sterilization Section Palm fresh fruit bunches are transported to the sterilization tank using a scraper conveyor and a fruit cage to perform high temperature sterilization .(145 ℃ ,90-120 minutes) .so as to effectively control the free fatty acid content in the raw materials, and provide basic conditions for subsequent processing. Sterilization tank model 1.Horizontal 2. Vertical Customers can choose the type of sterilization according to their actual situation. |

|

| 03 |

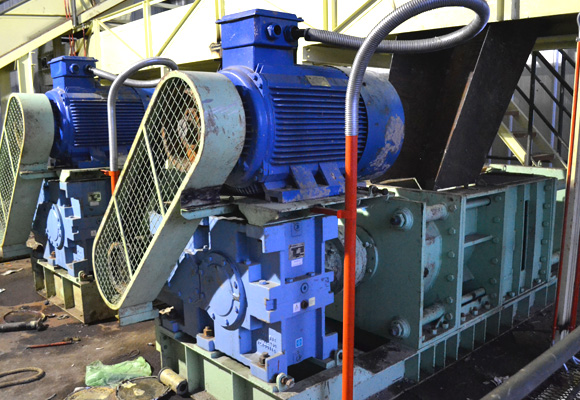

3.Threshing section Fresh palm fruit bunches are sterilized and transported to the thresher drum, which can separate the fruit particles from the bunches by rotating and beating. Mainly have the following characteristics: 1. Coaxial design; Adopt double-row self-aligning bearings to ensure coaxiality, strong stability, low failure rate and easy maintenance. 2. Adopt gradual start-up; The spindle has a large torque at start-up, which will cause great harm to the equipment and transmission equipment. We use the hydraulic coupler to gradually start at the motor end, and use the V-type belt connection motor reducer. Ensure the stability of the startup phase. |

|

| 04 |

4.Ripe Fruit pressing section The main equipment of the pressing station is digester and press machine: 1. The palm digester machine is mainly used for breaking the fruit and heating the fruit before the whole fruit enters the presser; The main models are: 2000L, 3000L, 3500L, 4500L. 2. Double screw press is double screw extrusion of the broken fruit, and equipped with a hydraulic system as an aid to ensure that the residual oil in the cake is reduced and the integrity of the palm kernel. The main models are: 5t (FFB) / h, 10t (FFB) / h, 15t (FFB) / h, 20t (FFB) / h |

|

| 05 |

5.Crude oil filtration section 1. Initial filtration of the hard and fibre impurities in the pressed crude palm oil; 2. Double filter, upper filter 20 mesh , lower filter 40 mesh 3. The filtered crude oil enters the crude oil tank, and the hard and impurities are recovered and repressed. |

|

| 06 |

6.Clarification station The main role of the Clarification oil section is to remove stearine and water from the oil by means of settling, centrifugation, vacuum drying and the like at an appropriate temperature. The main equipment is as follows: 1. palm crude oil shaker;(removal of impurities and hard ) 2. Vertical Clarification oil tank;(separation of dirty oil and clean oil) 3. Disc centrifuges;(separation of water in clean oil) 4. Vacuum drying system;(removal of residual moisture in clear oil) 5. Sand cyclone ;(remove the sand in the oil) 6. Three-phase decanter centrifuge(separation of oil,water,slag from dirty oil) 7. Crude Palm oil storage tanks.(palm oil storage) |

|

| 07 |

7.The storage of crude palm oil and transport 1.Palm oil crude oil heating storage 2.Crude palm oil transport |

|

| 08 |

8.Empty fruit bunches processing section: The residual oil is recycled, and the shredded empty fruit string is used as a fertilizer or fuel for the boiler. |

|

| 09 |

9 fibre separation section Through floating dry processing the fruit core and fibres separated. fibre and other lighter stuff was blown out.Separating the fibres in the pressed cake to obtain a pure core. |

|

| 10 |

10.Nut and Kernel Recycling section The kernel and the shell are separated by wind filtration and water washing according to the specific gravity of the shell and the kernel. After the separated kernels are dried, the water is reduced to about 6-8% for storage. The separated palm shell is transported to the boiler as fuel.The kernels in the core are recovered and stored. |

|

| 11 |

11.Steam Boilers 1. Has a strong output, high thermal efficiency, stable and reliable operation, overload capacity, fuel, wide applicability, environmental protection and many other advantages. 2. It Provides power and thermal sources for the production process. |

|

| 12 |

12.Power House 1.The use of diesel powered generators and turbine generators, more environmentally friendly energy production and electricity consumption to power. |

|

| 13 |

13.Raw water treatment system After settling, filtration, dosing and other processes to ensure that the water quality, but also to ensure oil quality. 1. Storage and settlement treatment of factory water 2. Filtration of factory water |

|

| 14 |

14.Boiler water treatment system 1. Select the water treatment system according to the water quality, generally divided into softening system and permeation reverse osmosis (RO system) 2. Remove Mg ion and K ion in water, adjust PH value of water, improve steam quality, extend boiler life |

|

| 15 |

15. Effluent Treatment |

|

| 16 |

16.Factory power control system 1.Diesel generators and steam turbine generators need to be switched. Each section is operated as a unit, which makes it easier to operate the entire plant and ensures the coordination of the entire plant. The key equipment adopts PLC control to ensure the operating efficiency of the equipment. |

|