|

01 |

1.Receiving section of raw material Palm oil press mill plant mainly make crude palm oil (CPO) by processes the extraction of fresh fruit bunches (FFB) collected by pressing and separate . 1.The main processes are: fresh fruit bunch receiving, high-temperature fermentation, threshing, oil clarification, oil storage; 2.The cakes are fed with fuel by means of fiber separation, nuclear fragmentation, shell separation, kernel storage, and fiber and shell collection. 3.The project is equipped with raw water treatment, boiler water treatment, steam boilers, turbine generators and diesel generators, fire protection systems, warehouses, laboratories, lightning protection systems and other utilities. The main output is 15t/h, 30t/h, 45t/h, 60t/h, 80t/h palm fresh fruit (FFB) |

|

|

02 |

2.Leaven-removal section The fermentation tank uses Thermal steamed steam to sterilize fresh fruit bunches(FFB) under a certain temperature and pressure environment , so as to effectively control the free fatty acid content in the raw materials, and provide basic conditions for subsequent processing. Mainly divided into the following types of concentration; 1. Horizontal biocidal tank; 2. Vertical bactericide tank; 3. Inclined canister; 4. Self-discharging canister; Customers can choose the type of canister according to their actual situation. |

|

|

03 |

3.Fruit separating section The fruit separater separates the fruit from fruit bunches by drum rotating fall down from the fruit-bearing skewer that has been fermented (SFB) One end feeds, the fruit drops from the grid, and the empty fruit bunch (EFB) is discharged from the other end to achieve the separation effect. Mainly have the following characteristics: 1. Coaxial design; Adopt double-row self-aligning bearings to ensure coaxiality, strong stability, low failure rate and easy maintenance. 2. Adopt gradual start-up; The spindle has a large torque at start-up, which will cause great harm to the equipment and transmission equipment. We use the hydraulic coupler to gradually start at the motor end, and use the V-type belt connection motor reducer. Ensure the stability of the startup phase. |

|

|

04 |

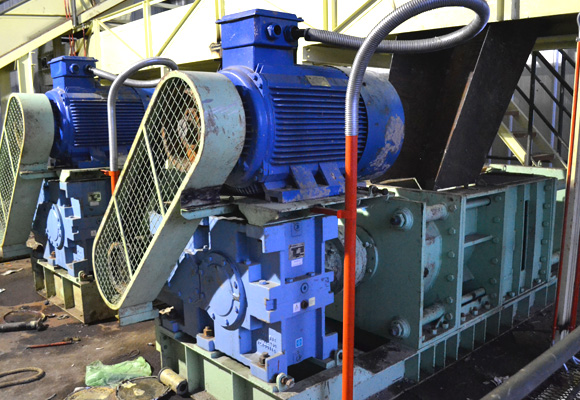

4.Fruit oil pressing section The main equipment of the pressing station is digester and press machine: 1. The mash tank is mainly used for breaking the fruit and heating the fruit before the whole fruit enters the presser; The main models are: 2000L, 3000L, 3500L, 4500L. 2. Double screw press is double screw extrusion of the broken fruit, and equipped with a hydraulic system as an aid to ensure that the residual oil in the cake is reduced and the integrity of the palm kernel. The main models are: 5t (FFB) / h, 10t (FFB) / h, 15t (FFB) / h, 20t (FFB) / h |

|

|

05 |

5.Crude oil filtration 1. Initial filtration of the hard and fiber impurities in the pressed crude palm oil; 2. Double filter, upper filter 20 mesh , lower filter 40 mesh 3. The filtered crude oil enters the crude oil tank, and the hard and impurities are recovered and repressed. |

|

|

06 |

6.Clarification station The main role of the Clarification oil section is to remove stearine and water from the oil by means of settling, centrifugation, vacuum drying and the like at an appropriate temperature. The main equipment is as follows: 1. palm crude oil shaker;(removal of impurities and hard far) 2. Vertical Clarification oil tank;(separation of dirty oil and clean oil) 3. Disc centrifuges;(separation of water in clean oil) 4. Vacuum drying system;(removal of residual moisture in clear oil) 5. Sand cyclone ;(remove the sand in the oil) 6. Three-phase decanter centrifuge(separation of oil,water,slag from dirty oil) 7. Crude Palm oil storage tanks.(palm oil storage) |

|

|

07 |

7.The storage of crude palm oil and transport 1.palm oil crude oil heating storage 2.crude palm oil transport |

|

|

08 |

8.Ren nuclear separation station 1. Palm fiber and nuclear separation (fiber separation and winnowing system) 2. Polished stone removal system for palm kernel 3. The crushing of the palm kernel 4. Separation of palm kernels and shells 5. Palm kernel drying storage |

|

|

09 |

9.Raw water treatment system 1. Storage and settlement treatment of factory water 2. Filtration of factory water |

|

|

10 |

10.Boiler water treatment system 1. Select the water treatment system according to the water quality, generally divided into softening system and permeation reverse osmosis (RO system) 2. Remove Mg ion and K ion in water, adjust PH value of water, improve steam quality, extend boiler life |

|

|

11 |

11.Steam boiler 1. Provide heat source for production process 2. Steam pipeline connection to steam turbine generator |

|

|

12 |

12.Power house 1. Stea |

|